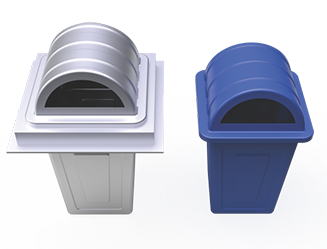

Comprehensive detail about Dustbin mould

Plastic dustbins are generally easy to measure and are made of energy-saving materials. Being used, in addition to the fact that it reduces many expenses, yet likewise has an ideal epitome for the improvement of administration life. In more homes, the utilization of dustbin manufacturers is likewise very normal, for example, rooms, kitchens, washrooms, parlors, and so on, are utilized all over, however, when they are utilized more, energy-saving and natural security in everyday life We additionally need to have a better than average of experience.

Dustbin mold making and plan

Plan necessities of a shaped plastic dustbin occasionally don’t permit the dustbin to be taken out straightforwardly from the plastic dustbin mold as it opens. This is genuine when the plastic dustbin is undercut concerning the line of movement or of the opening and shutting of the shape. The typical practice is to alter the plan however much as could reasonably be expected to make the least difficult shape.

The form would be somewhat massive—in any event, double the length of the dustbin to permit space for the dustbin and for the ejector travel. By embellishment over a center joined to a free bar, it will be feasible to shape lettering on the top substance of the case, as it will be drawn straightforwardly from the hole as the form opens. This plate has a roundabout mounting chief and is drilled out for the passageway of the infusion chamber nose.

On the infusion end, it is important to have a fairly huge opening to permit the infusion chamber to enter as close as conceivable to the shape to forestall unnecessary cooling of the plastics material. As it goes through the spout into the sprue. So a mounting manager has been remembered for the infusion end connector plate whenever they have to export it from Ahmedabad, Gujarat.