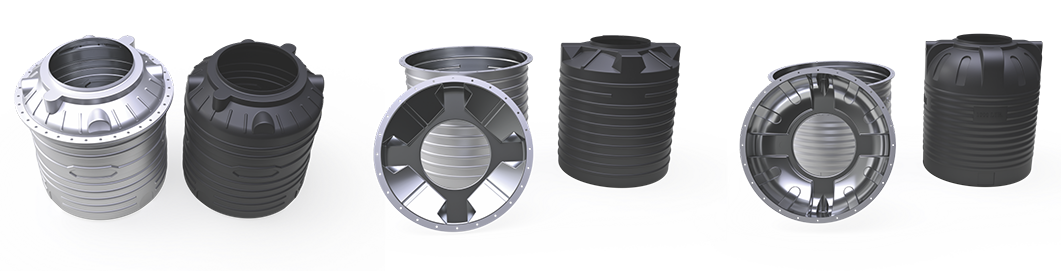

Significant key takes from the Water tank moulding process

It has been said previously, that the very truth that poly water tanks are made utilizing rotational embellishment gives them a colossal benefit over different sorts of water tanks like steel and fiberglass. You can likewise get key advantages from the leading exporters in India.

Why choose Water tank moulding?

We chose to make an exhaustive rundown of the full range of benefits roto-formed poly water tanks give that its partners proved unable. It’s practically uncalled for!

Rotational embellishment tanks are superior to blow formed tanks. Rotational embellishment tanks are produced using LLDPE though blow shaped tanks are produced using HDPE.

Benefits of Roto shaped tanks over Blow formed tanks:

Minimum material wastage: There is no any material wastage or material deformation during the moulding process.

Life time: Due to the actual interaction roto shaped tanks are accepted and demonstrated to have more life-time than blow formed tanks.

IS standard: According to the IS 12701, a level zone ought to be given on the highest point of the vertical tank for laborers to remain before entering.

Also, because of cycle limitations of blow forming it is beyond the realm of imagination to expect to have a level region on the highest point of the tank. Along these lines, blow formed tanks are not IS approved. Rotational shaping is in the less expensive tooling cost yet lower creation numbers and longer handling time contrasted with Blow Molding. Rotational Molding fits expert little run items.

Eventually, You can reach out to Kingroto for the best quality Water tank Mould in Ahmedabad. If you want to mainly concentrate on product quality, strengthen the material & thickness of the product, you can likewise connect with the best Manufacturers.