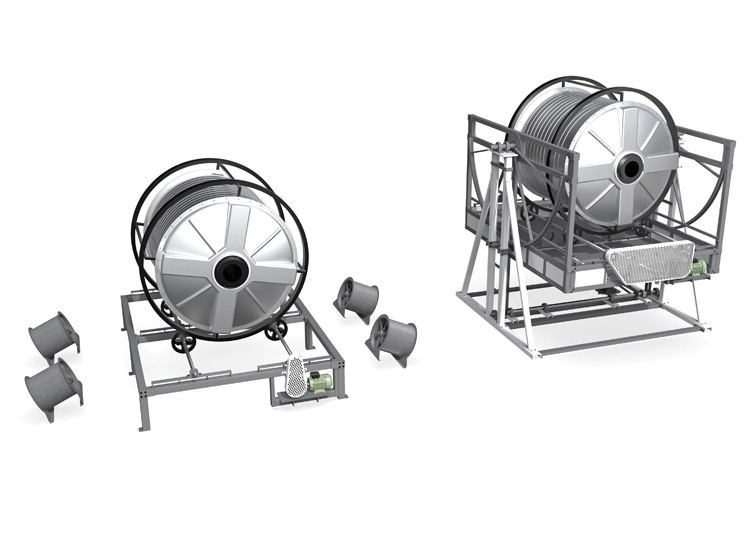

We are the leading Manufacturers and Supplier of Rock & Roll Rotational Moulding Machine and other machinery equipment. Rock & Roll Rotational Moulding Machine is also referred to as rotational molding and is widely preferred for its ability to offer a great number of benefits to manufacturers and industries across the globe. If you are wondering by rotational molding is amongst the widely preferred manufacturing techniques and we will walk you through the advantages and functionalities of rotomoulding machines. The enlightenment will undoubtedly help you in coming up with the most suitable decision with confidence.

Rotomoulding machines belong to the rotational moulding procedures that are a thermoplastic modelling process that can handle the molding and manufacturing of large components with easiness. Even the components as big as tanks and coolers can be efficiently handled with the help of a reliable rotomoulding machine.

Precise and High-Quality Finish

If you require working with components and parts that need to be taken care of with detail precision and high-quality finishes, then rotomoulding machines are definitely the best option that you could choose for the manufacturing of your products. The products that are equipped with thick-walled and high stability are often produced with the help of rotomoulding machines. The many features that belong to the rotomoulding machine that make it multiple times easier for the manufacturers to handle the process carefully under observation.

A hollow mould is first filled with powdered plastic resin. Then with the help of a rotomoulding machine, the mould begins to rotate and is transferred into an oven to move ahead with the procedure. Once the resin is hardened into the desired shape the rotation is stopped and the mould can be open to reveal the final product that is ready to be used on an industrial level.

| Model Rock N Roll | Floor Space (mm) | Floor Space for Cooling Station (mm) | ||||

|---|---|---|---|---|---|---|

| L | B | H | L | B | H | |

| King-KR-1000 | 3600 | 2500 | 1600 | 3600 | 2500 | 600 |

| King-KR-2000 | 3900 | 2800 | 2000 | 3900 | 2800 | 600 |

| King-KR-5000 | 4200 | 4000 | 3500 | 4200 | 4000 | 850 |

| King-KR-10000 | 6000 | 3800 | 3200 | 6000 | 3800 | 850 |

| King-KR-20000 | 7400 | 4500 | 3500 | 7400 | 4500 | 900 |

| King-KR-30000 | 8000 | 5000 | 3800 | 8000 | 5000 | 900 |